Discover the Significance of an Optical Fibre Diameter Analyser for Precision Dimensions

The precision of optical Fibre measurements is vital in the telecom field, where also the slightest deviation in Diameter can lead to significant signal degradation. An optical Fibre Diameter analyser offers as a critical tool to ensure these measurements are consistent and accurate, thus improving overall system performance.

Understanding Optical Fibre Diameter

Recognizing the Diameter of optical fibres is critical for making certain optimum performance in information and telecoms transmission applications. The Diameter directly influences the light-carrying capacity of the Fibre, influencing both signal stamina and high quality. Optical fibres generally are available in two primary classifications: single-mode and multi-mode, each with unique Diameter requirements. Single-mode fibers generally have a smaller core Diameter, around 8 to 10 micrometers, permitting the transmission of light signals over longer distances with minimal loss. In comparison, multi-mode fibres feature bigger core diameters, usually between 50 to 62.5 micrometers, which facilitate greater data transfer over shorter ranges.

The accuracy of Diameter dimensions is important, as also minute variants can lead to substantial inconsistencies in performance. Factors such as making resistances and ecological influences can impact the Diameter, requiring regular and accurate measurement strategies. Moreover, standardization in Diameter specifications makes sure compatibility in between different Fibre types and ports, decreasing the threat of system failures. As telecommunications modern technology remains to advance, the need for trusted optical Fibre Diameter analysis comes to be significantly critical, emphasizing the importance of using advanced measurement tools and approaches to preserve high-grade communication networks.

Advantages of Accurate Dimensions

Precise dimensions of optical Fibre Diameter are critical for maximizing network performance and dependability. The integrity of optical signals is directly influenced by the harmony and accuracy of Fibre diameters, as discrepancies can result in enhanced attenuation and signal destruction. By making certain that the Diameter of optical fibres is continually measured within defined resistances, operators can minimize losses and enhance overall transmission high quality.

Additionally, exact Diameter evaluations add to reliable Fibre splicing and connectorization. Mismatched diameters can result in inadequate coupling efficiency, leading to boosted insertion losses. This precision is specifically critical in high-speed networks, where even minor discrepancies can have significant influence on data transmission prices.

Additionally, preserving strict criteria for optical Fibre dimensions aids in conformity with industry guidelines, guaranteeing that items satisfy required requirements. optical fibre diameter analyser. This not only strengthens consumer self-confidence however also improves the credibility of suppliers and provider in the affordable telecommunications landscape

Eventually, the benefits of accurate measurements expand past immediate performance gains; they cultivate long-lasting integrity and resilience of network facilities, leading the way for future improvements in optical communication innovation.

Applications in Telecommunications

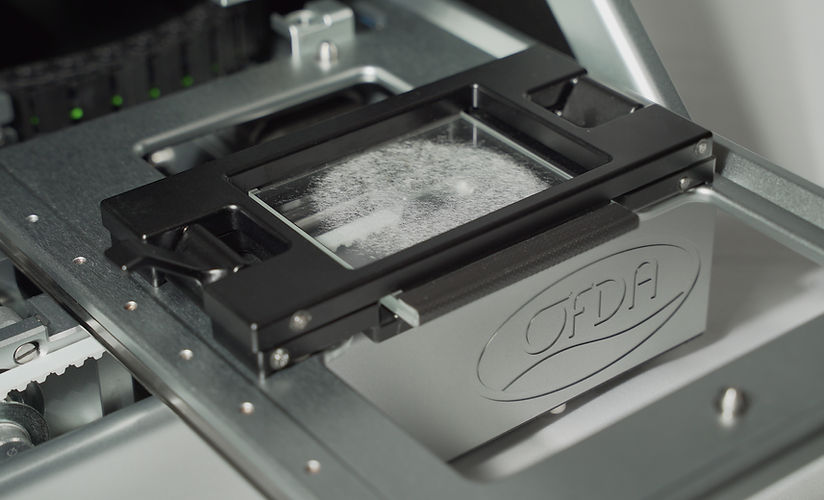

The applications of optical Fibre Diameter analysers in telecommunications are necessary for ensuring ideal network performance and effectiveness. optical fibre diameter analyser. These analysers play a vital function in the manufacturing, installment, and upkeep of optical Fibre cables, where accurate dimensions of Fibre Diameter substantially affect the total efficiency of interaction systems

In telecoms, keeping uniformity in Fibre Diameter is essential for minimizing signal loss and optimizing transmission top quality. Variants in Diameter can cause raised depletion and lowered transmission capacity, influencing information transmission prices. Optical Fibre Diameter analysers enable specialists to keep track of and control these measurements throughout the manufacturing official source procedure, guaranteeing that the fibres meet rigid specs.

Additionally, during installment and maintenance, these devices assist in verifying that the mounted fibres adapt the called for standards, thus preventing possible failures in communication framework. By utilizing optical Fibre Diameter analysers, telecommunications firms can improve their service integrity and customer contentment.

Top Quality Control Standards

In the realm of optical Fibre production, adherence to quality control criteria is paramount for guaranteeing the reliability and efficiency of interaction systems. The accuracy in optical Fibre Diameter is crucial, as variants can dramatically impact signal stability and total system performance. Producers need to apply rigorous quality control steps throughout the production process.

By adhering to well established high quality control standards, makers not only improve the efficiency of their optical fibres however also make sure consumer complete satisfaction and trust fund. Ultimately, robust top quality control practices are essential to the success of optical Fibre production and the improvement of interaction innovations.

Future Fads in Measurement Innovation

As the need for high-performance optical fibres rises, accuracy dimension tools will become increasingly essential. By incorporating real-time data and Visit This Link advanced sensors analytics, manufacturers will link be able to monitor Fibre Diameter variants with unmatched precision.

Moreover, the unification of non-contact dimension methods, such as laser triangulation and optical coherence tomography, will decrease the risk of contamination and physical damage to optical fibers throughout analysis. These advancements guarantee to enhance quality assurance procedures, making certain that just the most reputable products get to the marketplace.

Sustainability will certainly additionally play a vital duty in future measurement technology. Energy-efficient systems and recyclable materials will be prioritized, lining up with worldwide environmental standards. Additionally, the adoption of Industry 4.0 concepts will certainly help with smooth combination of dimension innovation within smart production environments, permitting continual enhancement and quick development.

Verdict

To conclude, the optical Fibre Diameter analyser acts as a vital instrument for making sure accuracy in telecommunications. Exact measurements straight enhance signal strength and transmission quality, thereby reducing signal loss. These analysers not just support quality control requirements yet likewise foster customer confidence in optical Fibre modern technologies. As the digital landscape remains to advance, developments in dimension technology will additionally strengthen the importance of these analysers in preserving ideal efficiency and reliability within the telecommunications market.

The accuracy of optical Fibre dimensions is paramount in the telecommunications industry, where even the smallest variance in Diameter can lead to substantial signal degradation. An optical Fibre Diameter analyser serves as an essential device to ensure these measurements are accurate and constant, thereby enhancing overall system efficiency. As telecoms modern technology proceeds to progress, the demand for trusted optical Fibre Diameter evaluation ends up being significantly vital, highlighting the value of utilizing advanced measurement devices and techniques to preserve premium interaction networks.

Precise dimensions of optical Fibre Diameter are pivotal for optimizing network efficiency and dependability. Optical Fibre Diameter analysers make it possible for professionals to check and manage these measurements throughout the production process, guaranteeing that the fibres fulfill strict specifications.